1.The Operator places and orients the tubes in the tube holders of the platform manually. (automatic tube place is optional )

2.This machine automatically fills, counts, sealing, cutting, codes and ejects the tubes.

3.High quality filling by volumetric pump and 3 ways valve. This device is very easy to dismantle, clean and sterilize.

4.All parts in contact with the product are corrosion proof (Stainless Steel for valve, pump and hopper, Teflon for piston).

5.Suck back device for the last drops of product at end of filling, nozzle giving a perfect cut off of product, & clean filling. Optional filling nozzle air cutter for preventing residue drop is available upon request.

6.Very easy regulation of dosing by variation of the piston stroke.

7.Security device:<<NO TUBE→NO FILL→NO SEALING→NO CUTTING>>electrically operated,which operates on the cap of the tube.

8.Hopper Capacity 70 Liters. Optional heatable double hopper is available upon request.

9.For each diameter of tubes, a set of 16 tube-holders is necessary. This set can be changed in 5 minutes.Adjusting of platform (Depending on the height of the tube) is instantaneous.

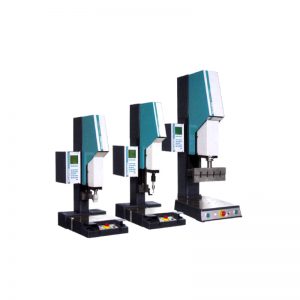

10.Instant ultrasonic tube sealing is favorable to avoid affecting the quality of the filled material which is easily influenced by other hot-welding methods.