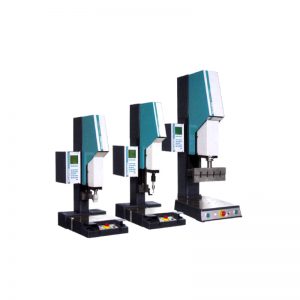

Multiplicity of versions for every requirement and every budget

The new design is the characteristic feature of all three press types USP400, USP750 and USP3000. The ma,. Nominal clamping forces are 400, 750 and 3000 N at 6 bar. The welding units come as standard or optionally with proportional valve and electronic pressure and path measuring systems according to the desired configuration level and press measuring systems according to the desired configuration level and press type. The operating frequencies of 20 or 36 kHz are set according to application.Ultrasonic generators in the 500 W to 5 kW output range are used according to press type and frequency. A principal feature of the extremely robust, torsionally stiff but nevertheless precision and low-friction welding presses is their modular construction, which allows use as a bench model or even as a feed unit on automatic production lines.

At a later date the USP3000 model is easy to upgrade as required from a lower output class up to 5 kW or be fitted with a multiconverter welding head. Even mixed operation between single converter and multiconverter configuration is possible!

Individual control options

There are various control options available, depending on requirements and wishes. The standard model MPS4basic includes all the basic

Functions for normal operation of the welding unit, data acquisition and quality control. More advanced functions, such as presetting of amplitude and welding pressure profiles and the incorporation of an additional card for other machine functions, come with the MPS4plus. The top-of-the-range model MPS4expert, with TelsoNetOnline software and integrated PC, keyboard and monitor or touch screen, also provides for remote maintenance via MODEM through the TELSONIC, Product Support Center and consequently satisfies the wishes of the most demanding of users.

Multiple welding head with compound sonotrodes

The robust construction of the USP3000 welding press and a maximum clamping force of 3000 N allows the use of up to three 20 kHz oscillating systems with large, complex mother/daughter sonotrodes. The multiconverter welding head is shown as a single oscillating system as a «snap-in» unit and can be replaced as required by another welding head at any time without any great expense of time in a quick-change process. The double-head version shown, for the welding of dishwasher spray arms, is fed by two 5000 W ultrasonic generators (total output 10 kW) and contains two mother sonotrodes each with nine insert sonotrodes, constructed as a «quick-change welding head» for another spray arm type.

Proven 500 Watt multiconverter technology

Multiconverter units are frequently used in the welding of large-area, asymmetrical or very precise plastic parts, as occur for example in automobile and apparatus engineering or with toys. The advantage of these TELSONIC multiconverter systems lies in the construction of small, uncritical sonotrodes and in the facility to optimise the weld quality along the whole weld contour with local targeting and individually. Multiconverter configurations can be implemented on all press types, to a max. of 24 welding heads in the case of the USP3000. The illustration shows a 20 kHz, 18 way multiconverter head for the welding of water containers for vaporizers.