- SGM ultrasonic generator Import from Switzerland

- 3.5 inch colorful touch screen Chinese / English operation surface

- Automatically search ultrasonic frequency and 50%~100% amplitude adjustment

- Time welding mode

- Constant (Relative and Absolute position) welding mode

- Constant energy welding mode

- Constant power welding mode

- Nodal support booster made of hard Ti-Aluminum alloy

- Constant energy welding mode

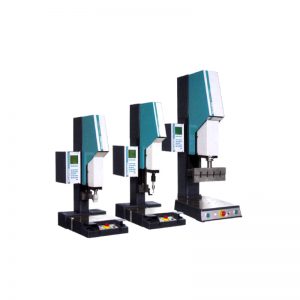

BSG Plastic Welding Machine

*SGM ultrasonic generator Import from Switzerland *3.5 inch colorful touch screen Chinese / ..

Block "product-contact" not found

Feature

1.Direct Parameters Input

Convenience Chinese / English HMI, easily to input multiple welding modes. Like welding time absolute distance,relative distance, energy control, power control, constant time ,touch trigger。Could save 50 sets of welding program, also could choose and add many function ,because the function is strong,use easily, extend without limited, so won the best design award in 2007.

2.Ultrasonic Amplitude Adjustment

Amplitude able to be set 50%~100% output according to the welding request

3.Magnetized Encoder welding depth measurement

Adopt precise linear encoder (precision 0.0050mm) to make welding distance control, in order to reach precision ±0.01mm on finished product.

4.Electronic Force Trigger

Make ultrasonic oscillation of each time on the same trigger pressure, to ensure every oscillation, appear the accurate welding state, reach to the best quality.

5.Shake Function

Especially equipped with (SHAKE) function, to prevent working piece stick to the horn even after welding.This function could be designed turn on or turn off on client’s demand.

6.High Efficiency Converter and hard Booster

High efficiency converter and exclusive Titanium booster, with the best resonance system and over 95% transform for mechanical and electrical of the converter and titanium booster, which will offer the most stabilization and high bprecision, the best support method.

7.Machine Construction 20 KHz machine 100mm Strengthened rectangular pillar, collocate 100mm height base plate , machine can reach the quality request 100% while welding the product.

8 .Machine Modulize

Machine body, ultrasonic generator, and ultrasonic controller are all modulized to sure high quality of mahchine.

9. Welding Data Management / Storage (option)

Able to connect with computer for storage, management and print out of each information.

10.Welding quality control reveal

There is out of time welding safety reveal and every real out put data reveal after welding.In order to protect the damage cause of the wrong operate or process product bad.

Technical Information

| Technical data | |||

| Model | BSG-2012 | BSG-2020 | BSG-3512 |

| Ultrasonic freguency | 20KHz | 20KHz | 30KHz |

| Ultrasonic power | 1200W | 2000W | 1200W |

| Supply voltage 50/60Hz | 220V/1P | 220V/1P | 220V/1P |

| Control votage | 24V | 24V | 24V |

| Welding pressure | 80N-1500N | 80N-1500N | 80N-650N |

| Weight | 100KG | 100KG | 75KG |

| Dimension | 500mm X 650 X 1100mm | 450mm X 750mm X 880mm | |

Related products

CAN Bus Communication The hybrid ultrassonic generators provide for the digital input of all weld..

*Posit amplitude to protect the circuit *LED Ultrasonic frequency display *LED Ultrasonic load..

FUNCTION: All installations and equipments for producing gas lighters should be explosion-proof t..

*Anti-interference generator *Hand gun welding handle Our company policy insists always on con..

The modern ultrasonic generator with Amplitude Regulated Power System ARP is the result of m..

*SGM DHG ultrasonic vibration Import from Switzerland *Chinese / English touch screen operation&n..

FUNCTION: 1.Easy for operation,application range wild. 2.After welding could be waterproof、air..

Multiplicity of versions for every requirement and every budget The new design is the characteris..