The benefits at a glance

- Easy menu-driven operation

- Large graphics display for multi-line user control and welding curve display

- Menu-specific function keys

- Integrated help system

- Up to six different monitoring windows at a time for quality control

Quality process monitoring

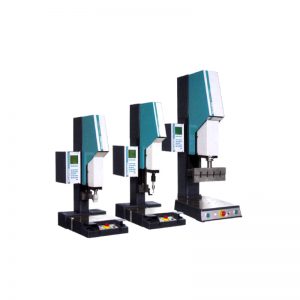

A new generation of control systems has been developed to make working easier and more readily assessed for the user when using ultrasonic joining technology. The MPS-4 is available in three versions and can be used with all Telsonic welding systems.

The advantages – at a glance

1.Easy to operate menu control and written-out texts.

2.Easy to operate menu control and written-out texts. welding curve display.

3.Integrated help system.

4.Same basic module for all designs.

5.Five different monitoring windows for quality control.

Quality through process monitoring

Considerations such as user friendliness, constancy of weld quality, complete process control and remote access to the welding units for maintenance purposes are growing in importance. To meet the different wishes and requirements of users, we can offer various versions of the welding process controller MPS4 with additional options. The standard model MPS4basic can be combined with all pneumatic welding presses, feed units and ultrasonic generators.

Data acquisition and statistical process control (SPC) with TelsoData

The optional TelsoData software can be used for displaying all the welding data, including output, pressure and welding path curves, clearly on the screen, saving them on an external PC or laptop. The integrated statistical process control program meets current quality assurance standards. Frequency distributions and trend profiles can be displayed for all the relevant welding parameters, such as output, energy, time, pressure and path. In addition, the program calculates all the characteristic statistical indicators, such as maximum, minimum, mean value, variance and standard deviation.

MPS4plus model

For more advanced requirements of welding process options and PC communication facilities the MPS4plus model offers the user interesting additional functions. This type of controller is also used for the control of the ultrasonic servo welding unit USP750servo.

The additional functions at a glance

- Presetting of amplitude and welding force profiles

- Control of servo presses (presetting of pressure/ or path/speed profiles)

- Digital inputs and outputs for additional functions (SPS functionality)

- Digital inputs and outputs for additional functions (SPS functionality)

- Operation:with optional TelsoNet communication software and external PC

The MPS4expert controller version can satisfy even the most demanding of users. The controller contains a PC with monitor and keyboard as standard. Alternatively, for even easier operation, a touch screen can be supplied. With the appropriate arrangements at the customer’s end the TelsoNetOnline software supplied as standard allows remote access via a MODEM.

In the event of technical or user-related questions contact with the TELSONIC Product Support Center can be made direct from the machine by sound and vision by way of the normal telephone network. This allows an application engineer at the remote TELSONIC service center to analyse the statistically evaluated welding data and curves and in the event of variations or irregularities to take immediate corrective action by appropriate alteration of the welding parameters.