Thermal trimming systems with shape cutters are used in the automotive supplier industry.

They are suitable for efficient, cost-effective cutting of

– flat and shaped motor-vehicle carpeting

– internal motor-vehicle trims

– laminated and in-mould decorated door trims

– A, B and C pillars

– rear shelves

– roof liners

– foam insulation systems for doors

– shaped non-woven elements

– map pockets

– seat coverings and head-rests

– airbag covers.

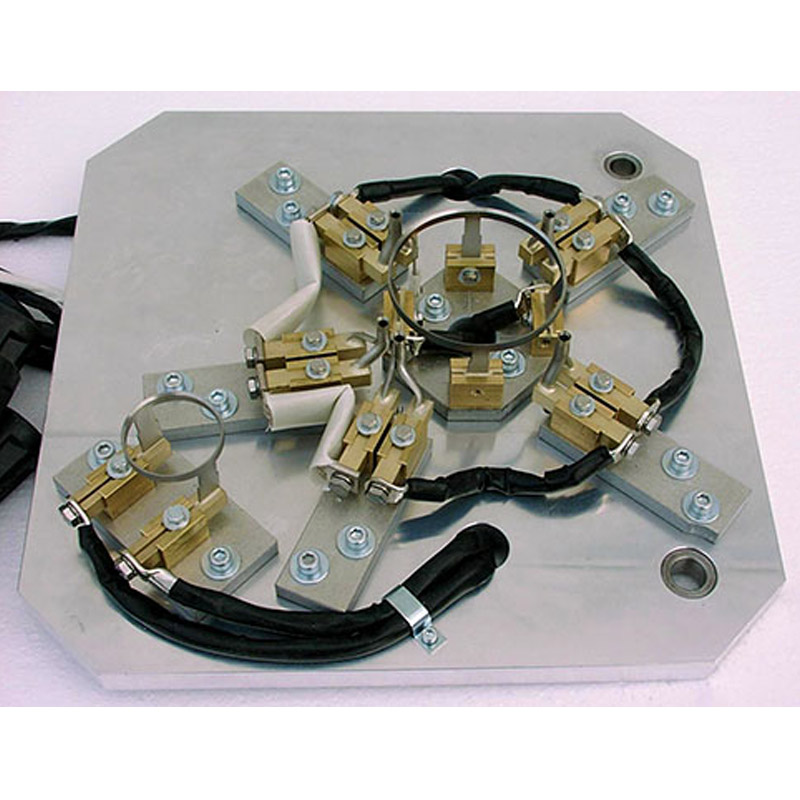

On airbags, laminated layers of fabric which require thermal cutting or hardening, and fixing, are located around the inlet and outlet openings and around the perforations for fixing of the gas generator.

Thermal trimming with shape cutters is a suitable process in this context. All the cutters for the openings and perforations can be integrated into a combined tool.

The combined tools can be used in an individual machine, or integrated into robot sewing units.

The handling, structure and heating of the shape cutters is identical to that of the cutting lines described above.

Thermal trimming with shape cutters is a more cost-effective, quicker alternative to laser trimming.

Airbag Trimming Tool (Detail)