- SGM DHG ultrasonic vibration Import from Switzerland

- Chinese / English touch screen operation

- Ultrasonic frequency automatic track

- Constant energy welding mode

- Constant distance welding mode

- Precision measure with Magnetized encoder

- Nodal support booster make of hard

- The largest welding pressure 4000

- The newest technology, the nodal horn have a patent, and the strongest support option compare to the same industry.

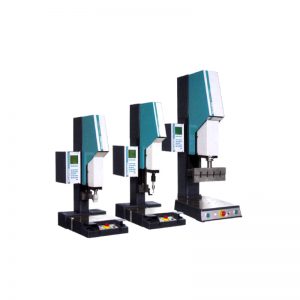

ULTRASONIC METAL WELDING:

1. The structure is precise, strong and easy to operate.

2. Short welding time, welding can be finished within a second.

3.Because of momentary high temperature welding, the temperature of the work piece will not exceed its temper temperature, thus it will not affect the quality and physics of the product, and its welding strength is higher than resistance welding or normal electrode welding, and will not damage the welded surfaces (no damage of metal properties) and the welding joint is smooth and clean.

4. After welding, the work piece has good electric conductivity, and its resistance coefficient is very low.

5. If there is any contamination or oxide coating on the metal surface, it can be welded perfectly.

6.No need of solder, welding flux or add other things to help welding , therefore, it can be welded economically and conveniently.

7.The welding horn, and jigs are made of steels, durable and long service life. And could choose the changeable horn.

8. No sparks during welding. No smoke, therefore no air-pollution problem , safety for the operators.